Know how CNC machining in mining maintenance can extend the lifespan of equipment. Call Aero Spec Engineering at +613 9547 8178 to ensure precision and quality.

The mining industry takes advantage of a wide range of heavy-duty equipment pieces and machines to ensure the success of its operations, especially when it comes to extracting materials, transferring ground elements, and so on. These things, however, may deteriorate over time due to repeated exposure to elements. They can also get damaged due to impact, abrasions, overloading, improper maintenance, vibration, and electrical failures.

One way to maintain and service mining equipment pieces is through computer numerical control (CNC) machining.

Common CNC Machining Processes

CNC machining is a versatile and precise manufacturing process that takes advantage of computer-controlled machines to remove material from a workpiece, creating custom parts and components. To date, several common CNC machining processes can suit specific applications and materials. Some of them are as follows.

• Milling: CNC milling takes advantage of rotating cutting tools to remove material from a workpiece. This special process is suitable for producing a wide range of shapes and features, including pockets, slots, and complex 3D contours.

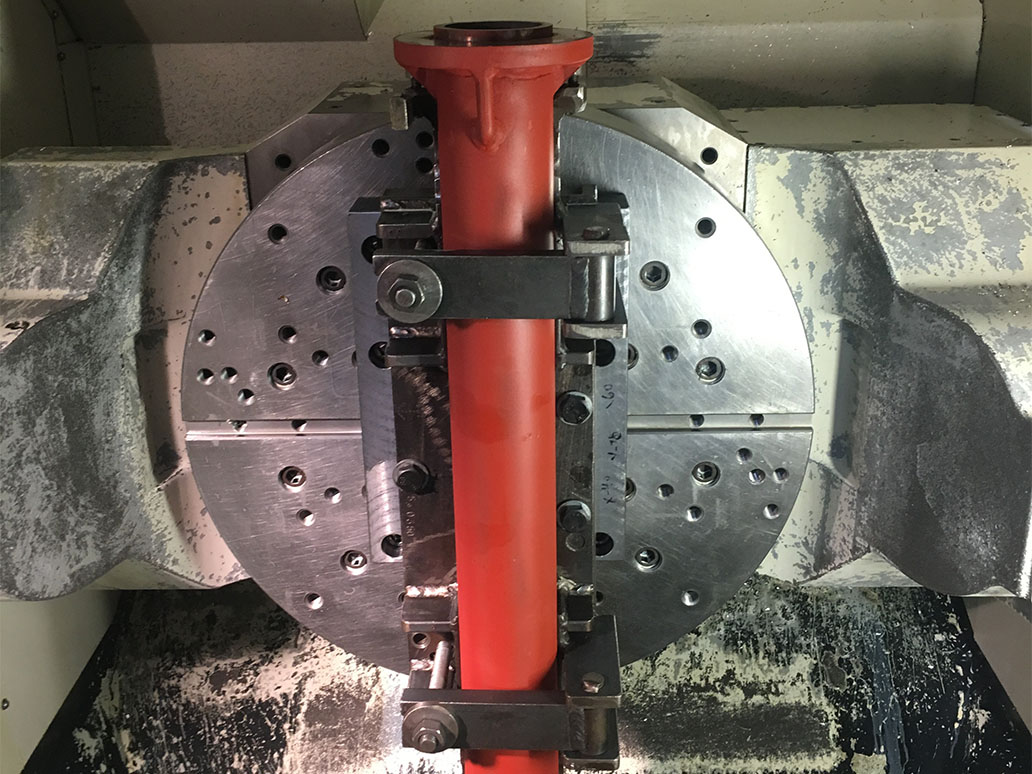

• Turning: CNC turning, also known as lathing, is used to create cylindrical parts by rotating the workpiece against cutting tools. This process is ideal for producing shafts, pins, and other round components needed by mining equipment pieces.

• Drilling: CNC drilling can create holes in a workpiece using specialised drill bits. This process can produce both simple and complex hole patterns with precision.

• Grinding: CNC grinding uses abrasive wheels to remove material, providing high precision and surface finish. This process is often used for producing precise components with tight tolerances.

• Electrical Discharge Machining (EDM):EDM is a non-traditional CNC machining process that uses electrical discharges to remove material. It can be maximised for hard and difficult-to-machine materials, such as tool steels and conductive ceramics.

• Wire EDM: This variation of EDM uses a thin wire as an electrode to create intricate shapes and features in a workpiece. Wire EDM is known for its accuracy and fine surface finish.

CNC Machining and Mining Industry

CNC machining, which is offered by Aero Spec Engineering, can be maximised to extend the lifespan of mining equipment.

For one, we can utilise CNC machining to repair critical components. This process can generate parts to replace those that are already worn or damaged, all with their original specifications. CNC machining can also help fabricate custom parts tailored to the exact requirements of the mining equipment, saving both time and money. This service can also ensure all components will fit perfectly, reducing friction and wear. It can even manufacture and replace parts quickly, minimising equipment downtime and keeping mining operations running smoothly and cost-effectively.

CNC machining by Aero Spec Engineering is also useful in producing complex components, ensuring consistent quality and adherence to tight tolerances, and extending the lifespan of mining equipment.

We, at Aero Spec Engineering, offer CNC machining services for maintaining and servicing mining equipment pieces. We help provide precision repairs, custom part fabrication, and improved durability for critical equipment. By extending the lifespan of mining equipment, operations can increase efficiency, reduce downtime, and ultimately improve their bottom line.

Optimized by: Netwizard SEO