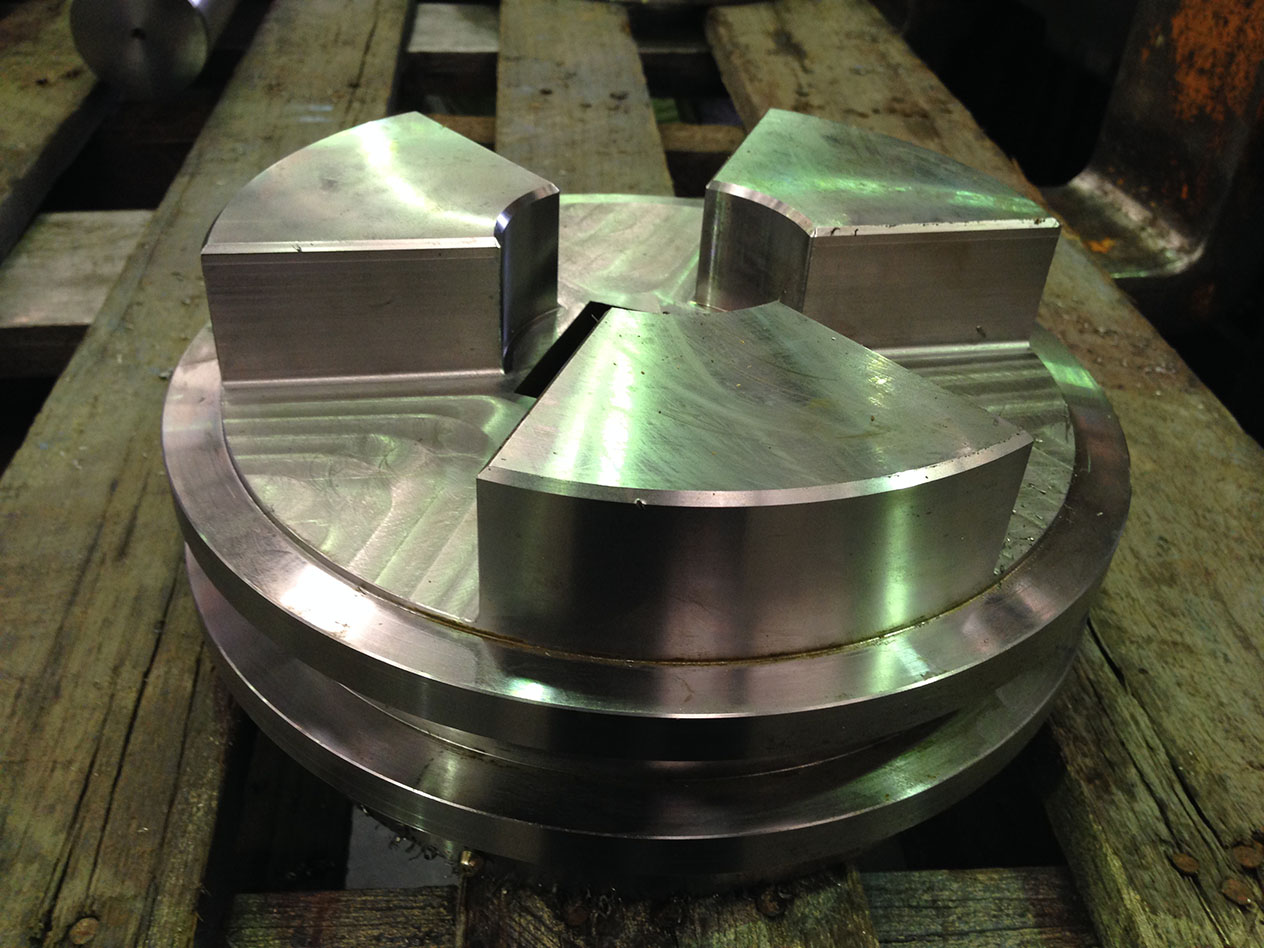

Expert conventional turning by Aero Spec Engineering in Melbourne delivers precision for complex steel designs, ensuring accuracy in every intricate detail.

Conventional turning is a time-honoured technique in machining that remains relevant for producing complex steel designs. Aero Spec Engineering fosters that this method, rooted in tradition, offers a unique blend of craftsmanship and precision that modern techniques often overlook. As industries evolve, the value of conventional turning becomes increasingly apparent, particularly for projects requiring intricate details and robust materials. Our team ensures that we harness the full potential of this technique, delivering components that meet the highest standards of quality and performance.

Precision and Accuracy in Conventional Turning

When it comes to conventional turning, precision and accuracy are non-negotiable. Our commitment to high-quality manufacturing means that we employ advanced techniques to ensure that each component is crafted to the exact specifications required. With a focus on detail, we guarantee that every turn of the lathe contributes to the overall quality of the product. By combining skilled operators with reliable machinery, we consistently achieve the high standards that our clients expect.

Versatility of Conventional Turning for Complex Designs

Conventional turning is not only about precision; it’s also about versatility. This technique can be adapted to a variety of applications, making it suitable for complex designs across different industries. Here’s how:

• Adaptability to Various Materials: Conventional turning excels in processing a diverse range of materials, from high-strength steels to softer metals like aluminium. This adaptability allows manufacturers to select the most suitable material for their specific design requirements.

• Precision Machining of Intricate Geometries: The ability to create intricate shapes and designs is one of the key advantages of this. Whether it’s achieving fine details or producing components with complex curves, this method provides the flexibility to meet various design challenges.

• Integration with Other Machining Processes: Conventional turning can easily be integrated with other machining techniques, such as milling and grinding. This synergy enhances workflow efficiency and allows for the creation of more complex assemblies in a single production cycle.

• Custom Tooling Solutions: Tailored tooling is essential for achieving the desired results in complex steel designs. Traditional turning allows for the creation of custom tools that can enhance precision and efficiency, ensuring that each component meets specific requirements.

• Application Across Diverse Industries: From automotive to aerospace and beyond, its versatility makes it a preferred choice in many sectors. Its ability to deliver high-quality components quickly and efficiently ensures that industries can meet their production needs without compromising on quality.

Incorporating traditional turning into our manufacturing processes has allowed us to cater to a broad spectrum of industries. Our experience and expertise in this area enable us to deliver solutions that meet the unique needs of each client.

Conventional turning offers unparalleled versatility and precision for complex steel designs. By embracing this technique, manufacturers can produce high-quality components that stand the test of time.

At Aero Spec Engineering, we pride ourselves on being industry experts in precision engineering and CNC machining. Our commitment to delivering accurately manufactured components spans various sectors, including transport, mining, recycling, and more.

Optimized by: Netwizard SEO