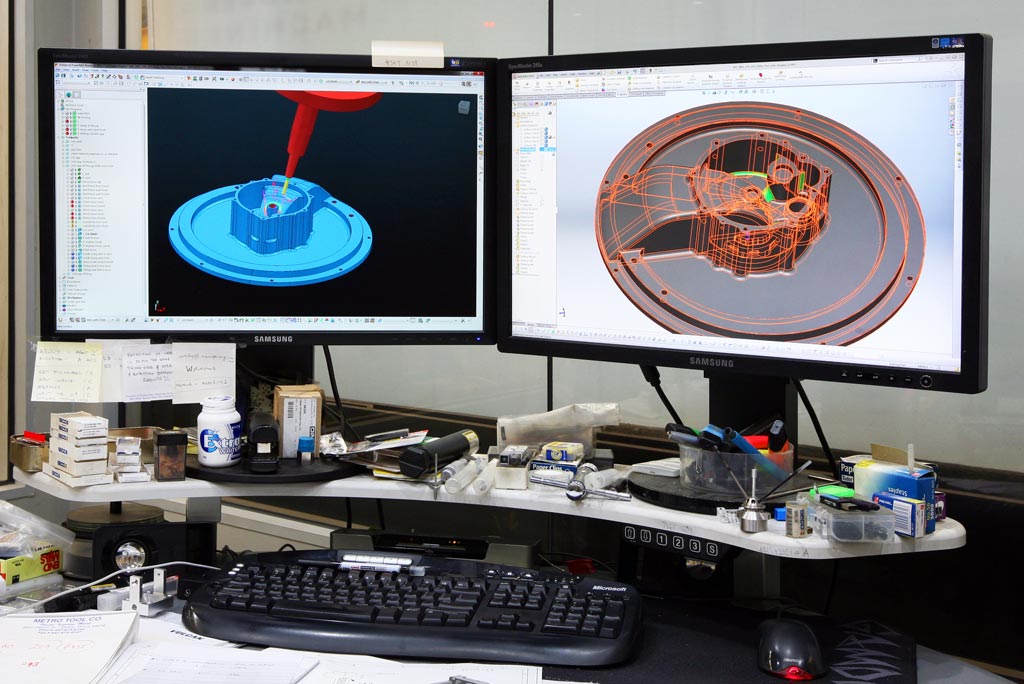

CAMs and CNC retrofitting represent pivotal advancements in contemporary manufacturing, offering streamlined processes through digital design and automated control. These improvements allow for increased precision, efficiency, and flexibility in manufacturing operations. Assurance that manufactured parts precisely conform to design specifications calls for the integration of coordinate measuring machines.

Enhancing Manufacturing Capabilities with CAMs and CNC Retrofitting

Modern manufacturing capabilities benefit significantly from the implementation of CAMs and CNC retrofitting. Reduced material wastage, minimised errors, and accelerated production cycles are achieved through digital design and automation. Extending the lifespan of existing CNC machinery via retrofitting provides a financially prudent alternative to complete machine replacement.

Improved precision in manufacturing arises from computer-aided manufacturing, facilitating complex designs previously unattainable. CNC retrofitting allows older machines integration with modern control systems, enhancing functionality and precision. These upgrades ensure equipment meets current demands, preserving capital investment and minimising operational disruptions.

The Role of Brown & Sharpe CMM in Accurate Part Inspection

Unparalleled accuracy in verifying part specifications comes from Brown & Sharpe coordinate measuring machines, ensuring adherence to stringent tolerances. Accurate part inspection remains critical, verifying each component meets the required design criteria and functional benchmarks.

Consider the following functions of Brown & Sharpe CMMs in part inspection:

• Dimensional Verification: Precise measurement of manufactured part dimensions is achievable with CMMs, guaranteeing alignment with specified blueprints and upholding quality. This ensures components meet exact size and shape requirements. Detailed reports generated by the CMMs confirm adherence to design parameters and aid in identifying any deviations early in the manufacturing process.

• Geometric Tolerance Analysis: CMMs undertake an assessment of geometric tolerances, encompassing form, orientation, and location, to confirm correct functionality within assemblies. Precise evaluation ensures seamless integration and operation of manufactured parts. Analysis of geometric deviations is vital for ensuring parts function as intended in complex systems.

• Surface Finish Analysis: High-resolution scanning provides detailed analysis of surface texture, a pivotal factor affecting part performance and longevity. CMMs enable manufacturers to refine surface characteristics for optimal performance. This advanced analysis assists in optimising the surface qualities of components for particular applications.

• First Article Inspection (FAI): Thorough first article inspections, conducted by CMMs, verify initial production samples meet all design and quality mandates before full production commences. Proactive identification and correction of discrepancies is ensured.

• Reverse Engineering: Existing parts without CAD models can be accurately digitised using CMMs, generating precise digital replicas for reproduction or design modifications. This facilitates efficient replication and improvement of components. The resulting digital models can then be used for further design refinement or immediate manufacturing replication.

• Statistical Process Control (SPC): Integration with SPC software allows real-time monitoring of manufacturing processes, enabling the identification of trends and variations to sustain consistent quality and minimise waste. Proactive management of manufacturing consistency is facilitated. This continuous monitoring assists in maintaining process stability and proactively addressing potential issues.

Explore our comprehensive range of machinery here at Aero Spec Engineering, tailored for diverse CAMs and CNC retrofitting applications.

Stringent inspection systems throughout design and manufacture ensure precision in CNC machined components and assemblies, Aero Spec Engineering. Using the latest CNC machining technology empowers complex and intricate machining contracts to the highest standards. Secure a partnership with us in delivering unparalleled precision and accuracy for superior outcomes in your manufacturing processes.

Optimized by: Netwizard SEO