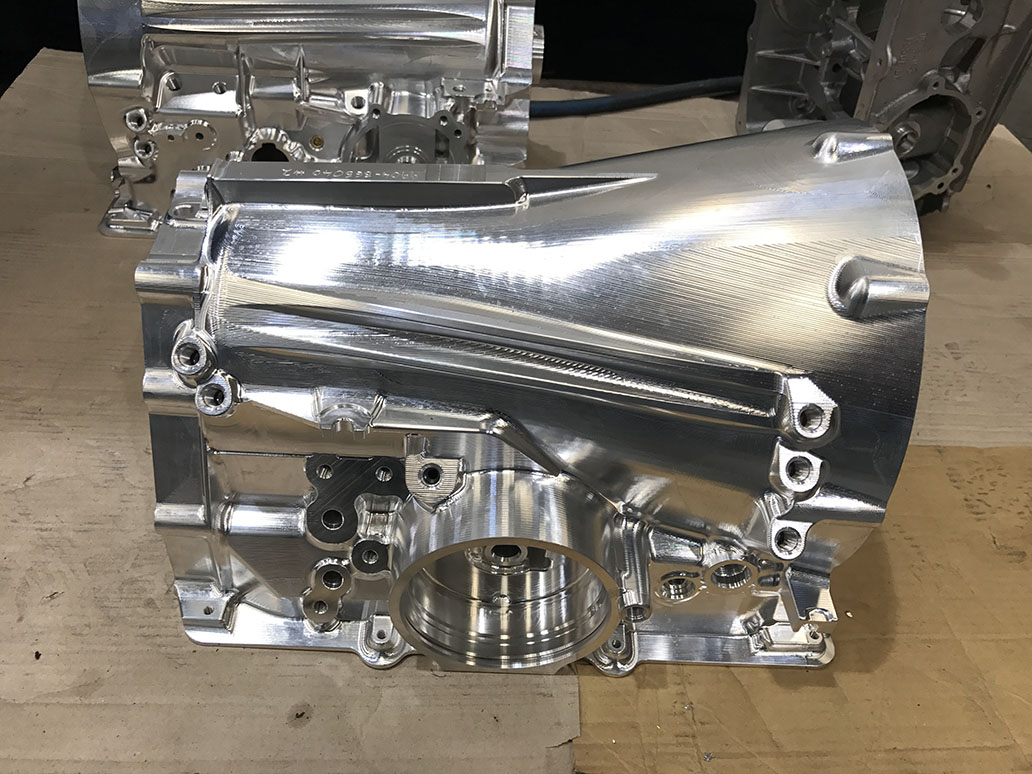

Streamline transport builds through CNC machined assemblies from Aero Spec Engineering, Melbourne’s leader in durable, high-tolerance fabrication.

Driving Transport Innovation with CNC Machined Assemblies

CNC technology enables consistent part replication, accommodating the large-scale production needs of Melbourne’s rail and road networks. Component uniformity ensures functional compatibility, reducing maintenance frequency and increasing mechanical efficiency.

Modern transport frameworks rely on mechanical continuity. CNC machined assemblies align with evolving transport design, simplifying integration into modular systems and contributing to streamlined maintenance programs.

Mechanical platforms across the transport industry integrate CNC-processed parts to meet the increasing performance expectations. Consistency in every machined output ensures greater lifecycle cost-efficiency and reliable field performance across transport infrastructures.

Melbourne’s Demand for High-Tolerance CNC Machined Assemblies

Precision machining remains central to Melbourne’s rapidly evolving transport infrastructure. The demand for exact specifications and repeatable output reflects both industry regulation and operational efficiency.

• Industrial Compliance: Machined assemblies are developed under strict adherence to national and local regulatory standards applicable to public and freight transport. Each unit is inspected to meet design tolerances required by Melbourne’s transport safety protocols.

• Integration in Large-Scale Builds: High-tolerance parts simplify assembly procedures for complex builds in rail cars, articulated vehicles, and other transport systems. Their dimensional alignment allows for seamless integration, reducing fabrication errors during final assembly.

• Reduction in Operational Downtime: Exact machining specifications eliminate uncertainty during part replacements, allowing mechanical systems to resume function with minimal delay. Reduced downtime leads to greater asset utilisation and project delivery consistency.

• Mechanical Durability: CNC assemblies are produced using high-grade materials and precise cuts to ensure structural resilience under mechanical loads and repetitive stress. This level of durability helps Melbourne’s transport infrastructure resist fatigue and wear over time.

• Optimised Resource Use: Efficient material removal and minimal scrap contribute to cost-effective production without compromising output quality. High-yield processes translate to reduced material waste and improved sustainability across transport projects.

• Adaptability to Transport Needs: Assemblies are tailored to suit a variety of transport formats including light vehicles, long-haul trailers, and rail freight systems. Each part responds to load-bearing and functional demands through accurate dimensional adaptation.

• Enhanced Operational Safety: Dimensional reliability minimises the risk of structural failures or mechanical mismatch during system operation. As a result, overall safety performance improves across transit vehicles operating in urban and regional zones.

Supporting Melbourne’s Transport Systems with Reliable Engineering

Through continued investment in advanced CNC methods, Aero Spec Engineering reinforces its commitment to supporting Melbourne’s transport industry. Every machined component reflects exact design standards tailored for local transport infrastructure, from urban vehicle applications to regional rail expansions.

Review our complete CNC machining capabilities developed to produce precisely engineered components for Melbourne’s transport infrastructure.

Explore how CNC machining supports automated workflows in modern production: CNC Machining in Packaging: The Significance of Automation in Modern Manufacturing

Discover how precision processes shape transport components through this blog: The Advantages of CNC Machining for the Transport Industry

Optimized by: Netwizard SEO