Achieve precision using EDM die sinking from Aero Spec Engineering in Melbourne for corrosion-resistant, dimensionally accurate marine components.

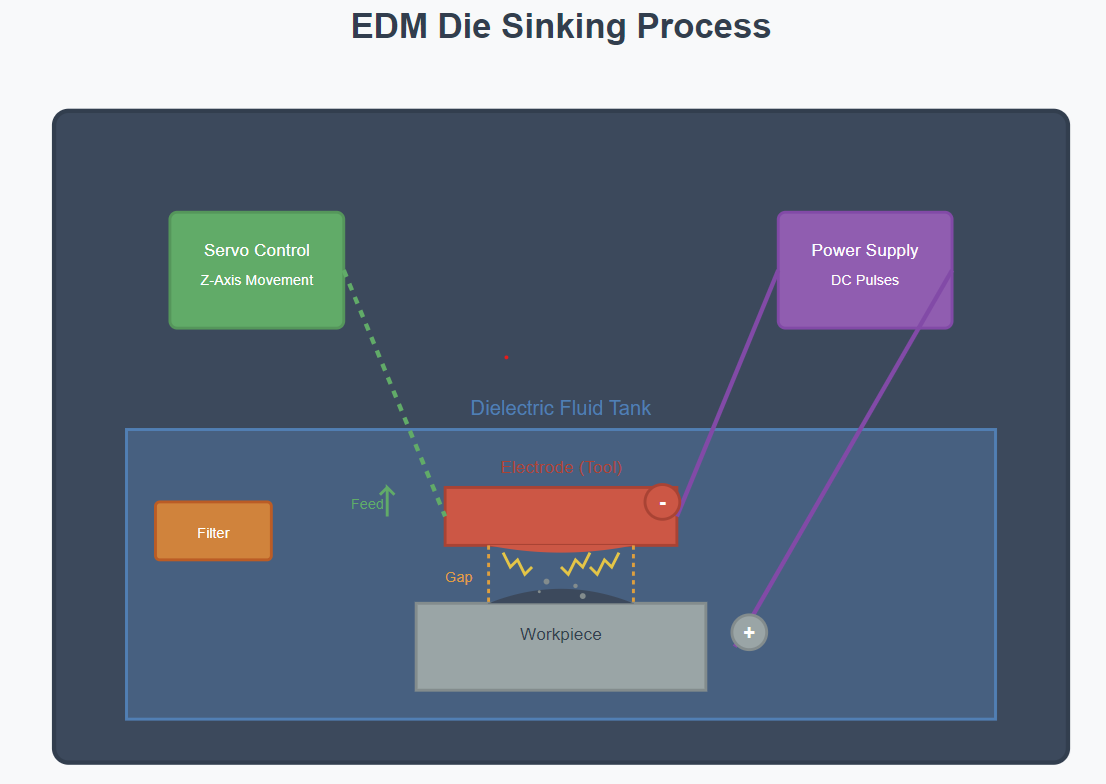

EDM die sinking provides a controlled method of removing material from conductive marine-grade metals to produce durable, corrosion-resistant components. Machining occurs without physical contact, allowing tight tolerances to be achieved on complex geometries without affecting the integrity of high-performance alloys.

Corrosion Challenges in Marine Components and EDM Solutions

Marine components must perform under extreme exposure to saltwater, vibration, and fluctuating pressures that accelerate surface degradation. Mechanical and thermal fatigue often shortens the life of conventionally machined parts, especially when protective surface layers are compromised during fabrication.

EDM cavity machining enables precise material removal without physical contact, preserving the structural and chemical integrity of corrosion-resistant alloys. This method prevents the formation of micro-cracks, pitting, or thermal-affected zones that weaken marine-grade materials. Metals such as duplex stainless steel, Inconel, and titanium retain their natural resistance to corrosion, allowing components to perform reliably over extended service cycles.

Dimensional Accuracy and Surface Integrity with EDM Die Sinking

Critical marine components rely on dimensional precision to support fluid dynamics and system sealing. Die-sinking EDM delivers tight tolerances essential to component alignment and mechanical performance.

Electro-discharge erosion forms clean edges and uniform surfaces suitable for contact-intensive functions. Part profiles remain consistent across production runs with no manual correction required.

• Achieves burr-free edges without additional surface finishing

• Prevents heat-induced microcracks or material distortion

• Maintains dimensional integrity across duplicate units

• Meets marine standards for precision mating surfaces

• Enhances fit, flow, and pressure reliability under stress

Integrating EDM Die Sinking in Modern Marine Manufacturing Workflows

Modern manufacturing operations prioritise efficiency, accuracy, and traceability from digital design to finished product. Die-sinking EDM integrates with CAD/CAM workflows, offering repeatable results aligned with 3D technical specifications.

Complex geometries can be processed directly from digital models, reducing human error and production delays. Automated systems support both short-run and scaled fabrication of marine components.

• Converts CAD files to exact tool paths without manual coding

• Supports lean production timelines and batch repeatability

• Minimises the need for fixture changes and tool swaps

• Reduces lead time from design approval to component delivery

• Supports traceable production data across multi-unit jobs

Engineering Marine-Grade Results – Aero Spec Engineering

Developed for challenging applications, Aero Spec Engineering machines high-spec marine components using EDM die sinking to ensure corrosion defence and dimensional consistency. The business produces precision parts capable of withstanding pressure, salinity, and mechanical strain across marine environments.

Contact us to secure corrosion-resistant marine parts manufactured through die-sinking EDM—built for endurance, accuracy, and seamless integration into your marine systems.

Learn more about the topic by exploring this blog: Sinker EDM: Process, Materials, and Applications

Optimized by: Netwizard SEO