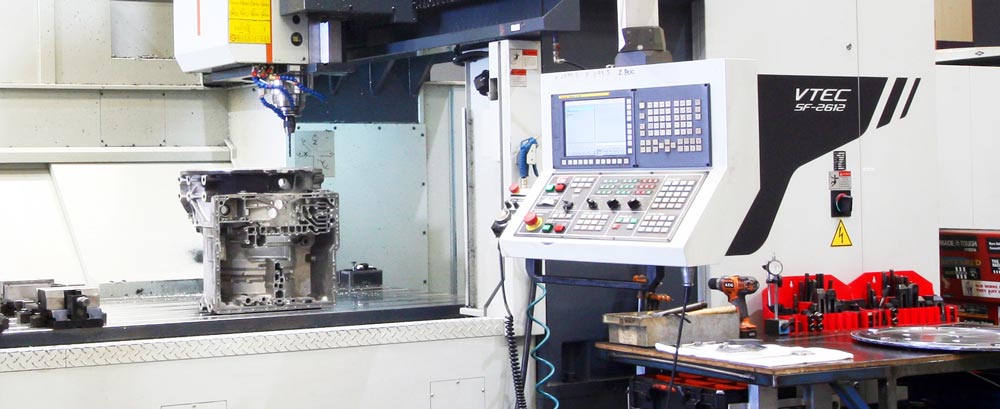

Choose CNC machining by Aero Spec Engineering in Melbourne to surpass traditional methods for precision parts, enhancing quality and production speed.

CNC machining delivers precise, high-quality components for industries such as aerospace, medical devices, and automotive engineering. It has transformed modern manufacturing with superior accuracy, efficiency, and repeatability. Manufacturers that invest in advanced machining processes are best positioned to meet the strict demands of clients and regulatory standards.

Why CNC Manufacturing Sets the Standard for Accuracy and Consistency

Unlike manual processes, precision machining uses computer-guided systems to execute every operation with pinpoint precision. This approach delivers several crucial advantages:

• Exceptional dimensional accuracy: Digital control ensures every part meets exact specifications.

• Consistent quality across batches: Parts remain identical, even in high-volume runs.

• Complex geometries with ease: Computer-controlled machining tackles intricate shapes that would challenge manual techniques.

• Reduced waste: Precision engineering maximises material use and minimises scrap.

• Superior surface finishes: Automated processes create smoother, more reliable results.

Speed and Efficiency: CNC vs. Traditional Techniques

CNC machining delivers superior performance in modern manufacturing by combining rapid programming-to-production turnaround, simultaneous multi-axis capability, and precise repeatability. Its ability to switch quickly between parts or projects and maintain reliable scheduling ensures exceptional throughput for both high-volume and urgent orders.

Traditional manual methods involve extended setup times, single-operation sequencing, and constant operator supervision, which limit productivity and consistency. These constraints lengthen lead times and increase the risk of variable quality, whereas CNC technology optimises every stage of production to achieve maximum efficiency without compromising accuracy.

Flexibility in Design and Prototyping

Modern industries need flexibility to innovate, update designs, and adapt to changing market demands. CNC manufacturing delivers unmatched agility in the design and prototyping phase:

• Effortless adaptation to complex or intricate geometries

• Instant modification of digital design files

• Rapid prototyping for product development

• Seamless transition from prototype to mass production

• Direct integration with advanced CAD/CAM software

The study on The Application of High-Speed CNC Machining to Prototype Production identifies that high-speed CNC processes achieve substantial reductions in lead times, enhanced precision, and streamlined prototype-to-production transitions through advanced toolpath optimisation and high-speed milling. Manual machining, with its longer setups, sequential operations, and higher variability, lacks the speed and consistency needed for rapid, scalable manufacturing.

Choose Aero Spec Engineering: Unmatched CNC Machining Expertise

Aero Spec Engineering leads the way in CNC manufacturing solutions, combining advanced technology, rigorous inspection, and a commitment to quality that’s second to none. From initial design to final inspection, every part is manufactured to exact requirements.

Our clients benefit from:

• Comprehensive machining facilities for all project needs

• Experienced professionals in computer-controlled and automated machining

• Quality assurance and a proven track record in precision engineering

Contact us to experience the difference that modern CNC manufacturing delivers.

Learn more about how precision machining streamlines large-scale production with this blog: CNC Machining Benefits for Large Scale Production and Manufacturing

Optimized by: Netwizard SEO