Offer precision-driven automation component machining in Melbourne with Aerospec Engineering, ensuring superior CNC quality for robotic applications.

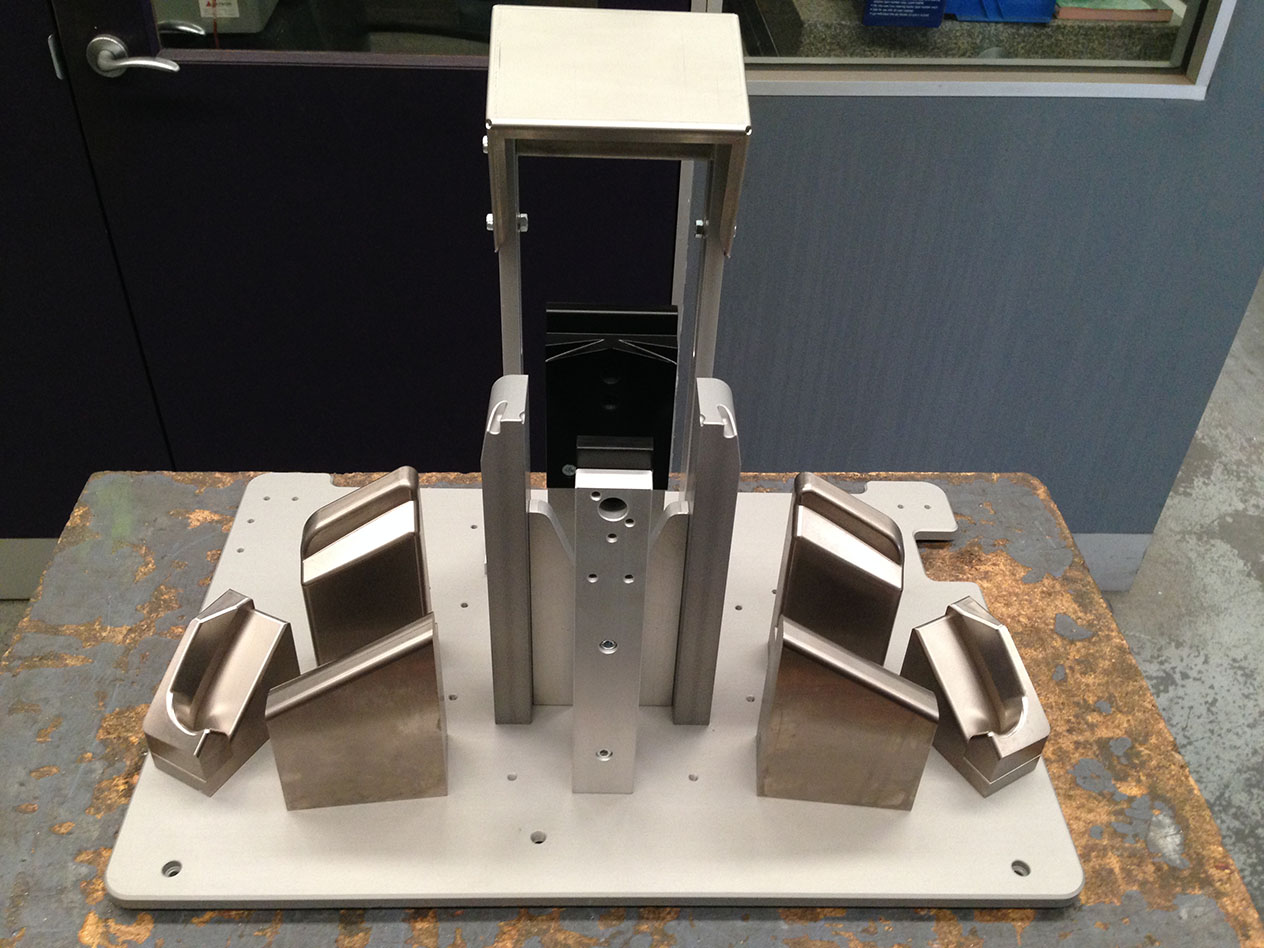

Automation demands exceptional accuracy and precision at every manufacturing stage. At Aerospec Engineering, we apply advanced automation component machining processes to deliver CNC-manufactured components that meet strict dimensional tolerances. Our precision engineering supports robotic systems used across diverse sectors, ensuring reliable performance under complex motion and load conditions.

CNC Precision in Automation Component Machining

CNC technology enables consistent quality and repeatability across large-scale production runs. Our facility utilises 3-axis and 5-axis CNC machining systems to manufacture components with complex geometries, fine surface finishes, and superior dimensional control. The process integrates advanced features such as:

• Multi-axis tool paths for machining intricate profiles and undercuts.

• Real-time calibration to sustain tight tolerance control.

• On-machine inspection systems for dimensional verification.

• Material versatility covering stainless steel, titanium, aluminium, and engineering plastics.

These capabilities enhance production accuracy and reduce downtime across robotic assembly applications.

Material Selection and Performance Assurance

Material suitability directly affects component stability, rigidity, and wear resistance. Our engineering team assesses dynamic loading, vibration impact, and thermal behaviour before selecting alloys or polymers that align with performance objectives. Each project undergoes rigorous metrology inspections—covering flatness, surface finish, and hardness—to ensure every machined part maintains consistent integrity.

Material suitability directly affects component stability, rigidity, and wear resistance. Our engineering team assesses dynamic loading, vibration impact, and thermal behaviour before selecting alloys or polymers that align with performance objectives. According to a study published in JMST Advances titled “Optimization Techniques for Material Selection and Manufacturing Processes,” evaluating both mechanical and thermal constraints is essential for achieving durable and high-performing machined components.

Precision Engineering for Robotic Systems

Evolving robotics technology requires machining accuracy at the micro level. Our automation component machining expertise supports OEMs and automation manufacturers seeking repeatable quality and fast turnaround. We deliver both prototype development and volume manufacturing with exact traceability through digital production control.

Our clients benefit from:

• Rapid CNC Prototyping for Design Verification – Accelerates concept validation through precise prototype machining that reflects final production quality.

• High-Volume Batch Production with Minimal Deviation – Maintains dimensional consistency across large production runs using automated process monitoring.

• ISO-Certified Documentation and Traceability – Ensures compliance and full visibility at every stage of the manufacturing process.

• Engineering Support Across the Full Product Lifecycle – Provides expert input from initial design consultation to post-production refinement.

• Adaptive Machining for Complex Robotic Components – Delivers reliable precision for intricate geometries and high-tolerance assemblies essential to advanced automation systems.

Achieve CNC Excellence with Aerospec Engineering

At Aerospec Engineering, we specialise in automation component machining that strengthens the precision and efficiency of robotic systems. Our CNC manufacturing capability ensures every component meets the highest mechanical and dimensional standards.

Explore our machinery to see the advanced machining technology driving our precision engineering results.

Contact us today to discuss your automation machining requirements and experience the technical precision that defines our engineering excellence.

Related Blog Article: Australian-made CNC Components for Industrial Automation – Precision Engineered & Certified

Optimized by: Netwizard SEO