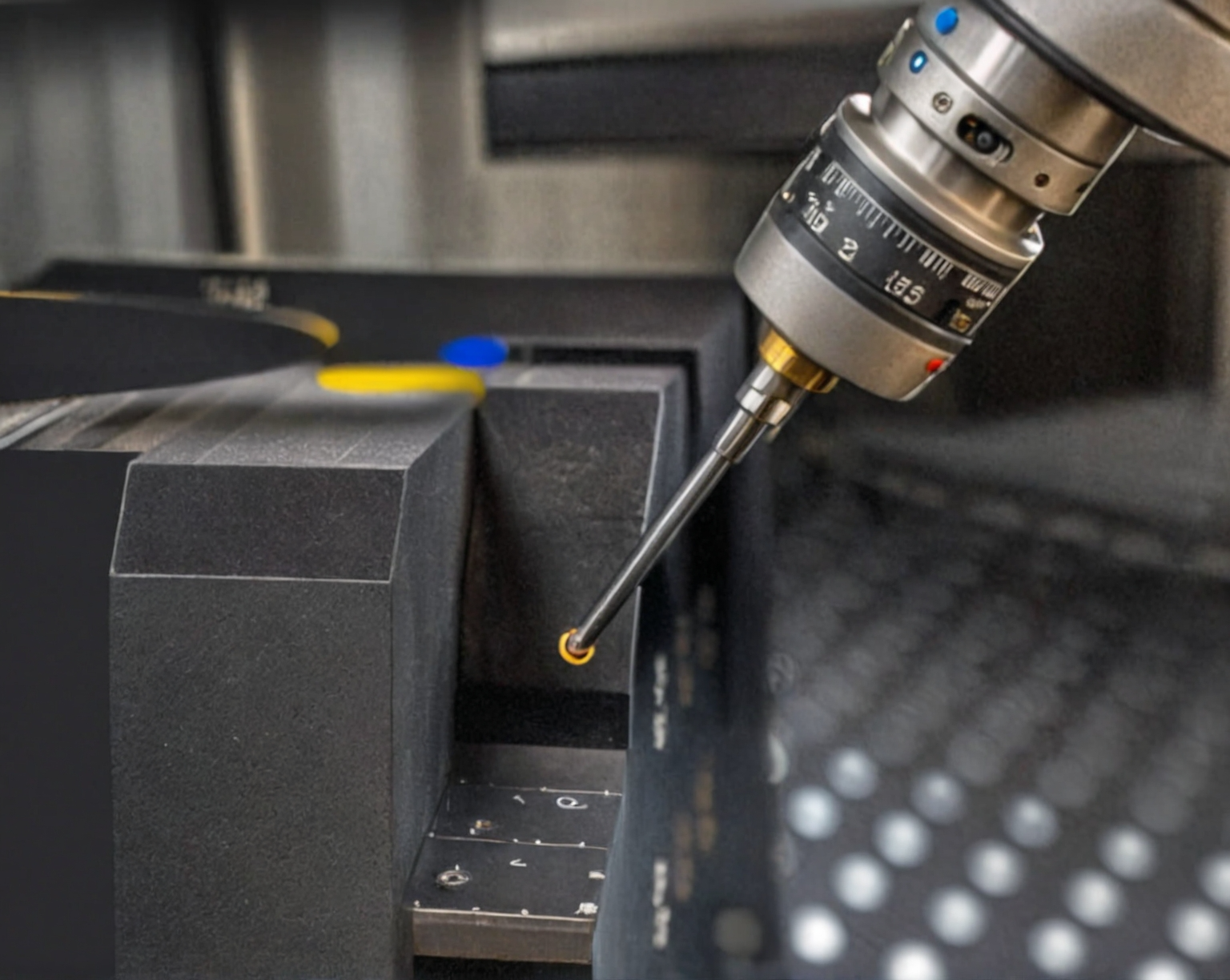

Aero Spec Engineering employs CMM inspection, a modern quality control method in precision engineering, ensuring unmatched accuracy and reliability.

CMM inspection is transforming quality control in precision engineering. This highly accurate method ensures that components meet stringent specifications, making it an essential tool in modern manufacturing. Production procedures are streamlined by CMM inspection, which lowers the possibility of mistakes and guarantees dependable uniformity at every level of the engineering services workflow.

Unveiling the Mechanics of CMM Inspection in the Engineering Process

CMM inspection utilises advanced probes and sensors that accurately measure components with exceptional precision, greatly reducing the need for manual input and mitigating potential human errors during the measurement process. These highly efficient systems harness the power of computerised technology, capturing real-time data that allows engineers to instantly verify whether the components meet the required specifications before proceeding to the next phase of production. The unrivalled accuracy provided by this technology ensures that all parts are kept within strict tolerance limits, effectively lowering the likelihood of defects and preventing costly rework or wastage.

The versatility of the computerised measurement process makes it an indispensable tool for various engineering sectors, capable of handling everything from mass production to complex, custom-designed components. This advanced system seamlessly accommodates a wide range of materials and intricate geometries, ensuring that each part is measured accurately and consistently across multiple production cycles. Businesses may streamline processes, cut down on manufacturing time, and continuously satisfy the highest quality requirements by putting automated quality control measurement into place, ensuring that every component operates dependably within its particular application.

Breaking the Mold: How CMM Inspection Surpasses Traditional Methods

CMM Inspection marks a significant improvement over traditional quality control practices, which rely heavily on manual measurements and subjective evaluations. This advanced technology delivers unmatched precision, faster processing times, and consistent results, ensuring adherence to stringent standards throughout production. Integrating precision measurement systems into manufacturing processes ensures reliable quality control and enhanced efficiency at every stage.

Below are several key factors that highlight its superiority:

• Unmatched Precision: CMM validation delivers micron-level accuracy, ensuring each component is measured to the highest standards.

• Speed and Efficiency: The automated process speeds up measurement, reducing production cycle times.

• Consistency: Unlike manual methods, CMM verification analysis ensures each part is measured the same way, eliminating human error.

• Instant Data Availability: Measurement results are instantly digitised, allowing for quick analysis and decision-making.

• Adaptability: The system can be tailored to measure a variety of materials, designs, and geometries.

• Cost-Effectiveness: Higher accuracy means less rework and fewer defects, which reduces costs in the long run.

• Enhanced Traceability: The digital nature of CMM calibration allows for better tracking and documentation, improving product traceability and compliance.

• Scalability: CMM monitoring systems can handle both small batches and large-scale production, offering flexibility in diverse manufacturing environments.

Aero Spec Engineering is distinguished in precision CNC machining, delivering expertly engineered components and assemblies that address the intricate demands of diverse industries. Our implementation of sophisticated CMM calibration technology ensures unmatched precision and unwavering quality across all production stages. Guarantee uncompromising accuracy in every part with our advanced engineering and inspection capabilities.

Optimized by: Netwizard SEO