CNC-Machined Stainless Steel Components and Parts for Automotive

17 October 2023

Experience precision and performance with CNC-machined stainless steel components for automotive. Partner with Aero Spec Engineering. Call +613 9547 8178.

Automotive is one of the industries that tend to evolve quickly. One key reason behind this is precision engineering since it plays a pivotal role in designing and producing high-performance vehicles that stand the test of time. CNC-machined stainless steel components and parts are the expected outcome of precision engineering, bringing unparalleled strength, precision and reliability to a wide range of automotive applications.

Here are some automotive applications of CNC machined stainless steel that continuously revolutionise the industry.

Engine

CNC machining is widely employed to craft intricate engine components from stainless steel. Some of these components are cylinder heads, pistons, and valves. The exceptional resistance of stainless steel to heat and corrosion ensures longevity and optimal performance under the most demanding conditions, which allows engines to run smoothly and efficiently.

Exhaust Systems

Stainless steel exhaust systems are a popular choice in the automotive industry due to their resistance to extreme temperatures and harsh environmental conditions. CNC machining ensures precise fabrication of exhaust components, securing improved exhaust flow, reduced backpressure, and enhanced engine power.

Suspension

Stainless steel suspension parts like control arms and sway bars are essential for maintaining vehicle stability and handling. CNC machining guarantees dimensional accuracy and tight tolerances, enabling suspension systems to perform flawlessly despite being exposed to and subjected to challenging terrains.

Braking Systems

CNC-machined stainless steel components are instrumental in manufacturing high-performance brake systems. From brake rotors to calliper brackets, stainless steel parts provide excellent heat dissipation, which minimises brake fade and improves braking efficiency.

Fuel System

The precision and durability of CNC-machined stainless steel are ideal for fuel system components like fuel injectors and pump housings. The resistance of stainless steel to corrosion and chemical damage ensures the integrity of the fuel delivery system, contributing to better fuel efficiency and reduced emissions.

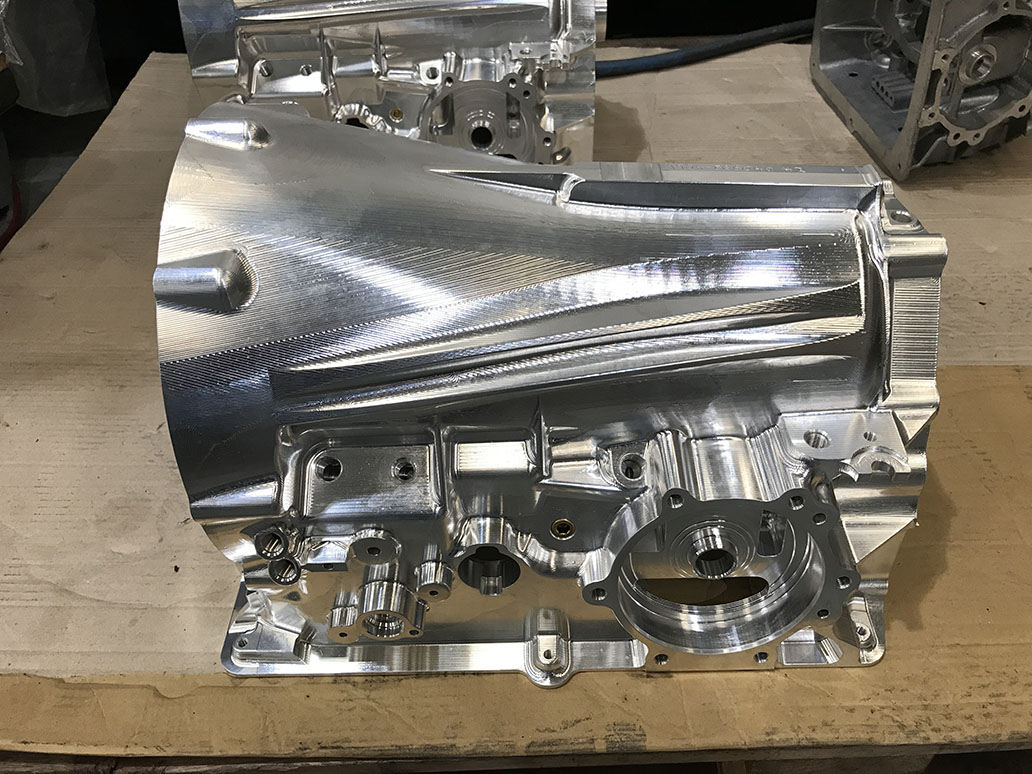

Transmission and Gearbox

CNC machining enables the creation of intricate stainless steel components used in transmissions and gearboxes. These parts withstand high torque and load, ensuring smooth gear shifting and transmission longevity.

Chassis and Roll Cage

Stainless steel components are commonly utilised in constructing robust chassis and roll cage structures. CNC machining guarantees that these critical safety components meet stringent quality standards, providing added protection to vehicle occupants in case of a collision.

With all the advantages maximised by stainless steel, it can help generate parts and products needed for performance upgrades. Stainless steel can be utilised by automotive enthusiasts in producing custom intake manifolds and turbocharger housings. This material can even be used to enhance the aesthetics and overall appearance of a vehicle.

CNC-machined stainless steel components have revolutionised the automotive industry by providing unparalleled strength, precision, and durability. All previously mentioned parts contribute to enhanced performance, reliability, and safety of vehicles. As technology continues to advance, CNC machining will undoubtedly remain a driving force behind innovation in the automotive sector, ensuring vehicles continue to meet the demands of the modern world.

Optimized by: Netwizard SEO