Conventional Grinding by Aero Spec Engineering: Why Skill and Expertise Matter?

04 December 2023

Explore the world of conventional grinding by Aero Spec Engineering. Understand why skill and expertise are essential. Call us at +613 9547 8178 today!

When it comes to manufacturing and precision engineering, few processes hold as much significance as conventional grinding. While it may appear straightforward, it is a discipline that requires a high degree of skill and expertise to achieve exceptional results. We, at Aero Spec Engineering, have mastered the craft of conventional grinding, making our service vital for many industries.

The Process of Conventional Grinding

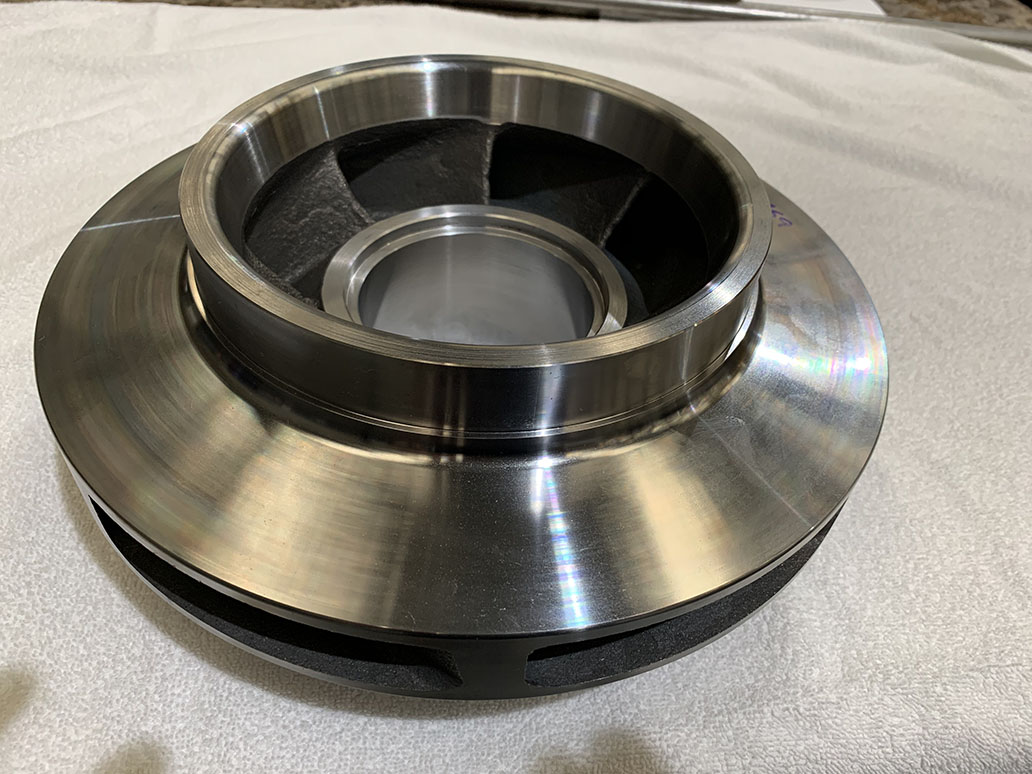

Conventional grinding is a material removal process that involves the use of abrasive wheels to create a fine finish or desired shape on a workpiece. It is a critical step in the production of numerous components across various industries, which include aerospace, automotive, and toolmaking. The process may look simple, but it still requires a profound understanding of materials, machinery, and precision to ensure the success of manufacturing projects.

This process is deemed to be ubiquitous as it plays a vital role in diverse industries. In the aerospace sector, it can be used for creating components with tight tolerances. In the automotive industry, it is essential for producing critical engine parts. Toolmaking likewise relies on grinding for shaping cutting tools. In each application, the skill and expertise of the grinder are instrumental.

Skill and Expertise are Highly Needed

Skill and expertise serve as the foundation of every manufacturing process. So, at Aero Spec Engineering, we make sure these things are established effectively to avoid any issues along the way.

Our team possess an intimate knowledge of materials, abrasives, and machinery. Their skill extends to the setup of the grinding equipment, the selection of the appropriate abrasives, and the precise control of the process parameters. They also have the ability to control the wheel, manage heat generation, and maintain the workpiece’s integrity, resulting in components that meet the most exacting specs.

Conventional grinding encompasses a wide range of materials, from hardened steel to delicate ceramics. Different materials pose distinct challenges, and our team’s expertise lies in understanding these intricacies. We must adjust parameters, such as wheel speed, pressure, and coolant application, to suit the material they are working with. Now, whether it’s a mirror-like finish for a high-precision optical component or a specific roughness requirement for an industrial tool, our expertise ensures that the surface finish meets or exceeds expectations.

Conventional grinding often requires customisation. Our skilled grinders have the capability to tailor the process to suit a particular workpiece or overcome challenges that may arise during grinding.

Partnering with Aero Spec Engineering

Conventional grinding is far from a routine process when executed by skilled professionals. It is a discipline that combines artistry, science, and meticulous attention to detail. The expertise of our team at Aero Spec Engineering ensures that the end products meet the highest standards of quality and precision. When you require precision components that meet the most stringent specifications, remember that behind the grinding wheel is a skilled artisan from Aero Spec Engineering whose mastery makes the impossible achievable.

Optimized by: Netwizard SEO