High Tensile Tool Steels in Modern Machining: Properties and Applications

05 October 2023

Uncover the properties and applications of high tensile tool steels in modern machining. Acquire them from Aero Spec Engineering. Call us at +613 9547 8178.

High tensile tool steels are a class of tool steels known for their exceptional mechanical properties, making them indispensable in modern machining applications. They generally exhibit high hardness, wear resistance, toughness, and strength that enable them to withstand heavy loads and high-speed cutting conditions. These qualities are present as they contain alloying elements like chromium, molybdenum, vanadium, and tungsten.

Properties of High Tensile Tool Steels

The composition of high tensile tool steels allows them to boast properties that make them valuable in modern machining. Some of these are as follows.

• High Hardness: One of the defining properties of high tensile tool steels is their impressive hardness. These steels often have a hardness ranging from 58 to 68 HRC (Rockwell hardness scale). These levels of hardness allow them to retain their shape and sharpness under severe mechanical stresses, which makes them ideal for cutting and forming.

• Wear Resistance: High tensile tool steels are likewise designed to withstand wear and abrasion, enabling them to highly suit machining operations involving friction and contact with other materials. Their wear resistance likewise ensures prolonged tool life, reducing the need for frequent replacements and enhancing machining efficiency.

• Good Toughness: Despite their high hardness, high tensile tool steels still maintain good toughness, which is crucial in preventing brittle fractures and catastrophic failure during machining. This property allows them to absorb impact and mechanical shocks, ensuring the longevity of cutting tools and components.

• High Strength: High tensile tool steels exhibit excellent tensile and compressive strength, enabling them to endure heavy loads and forces during machining. This property ensures the stability and reliability of the machined components in high-stress applications.

High Tensile Tool Steels Applications

All properties of high tensile tool steels make them effective in producing a wide range of modern machining tools. These tools include the following.

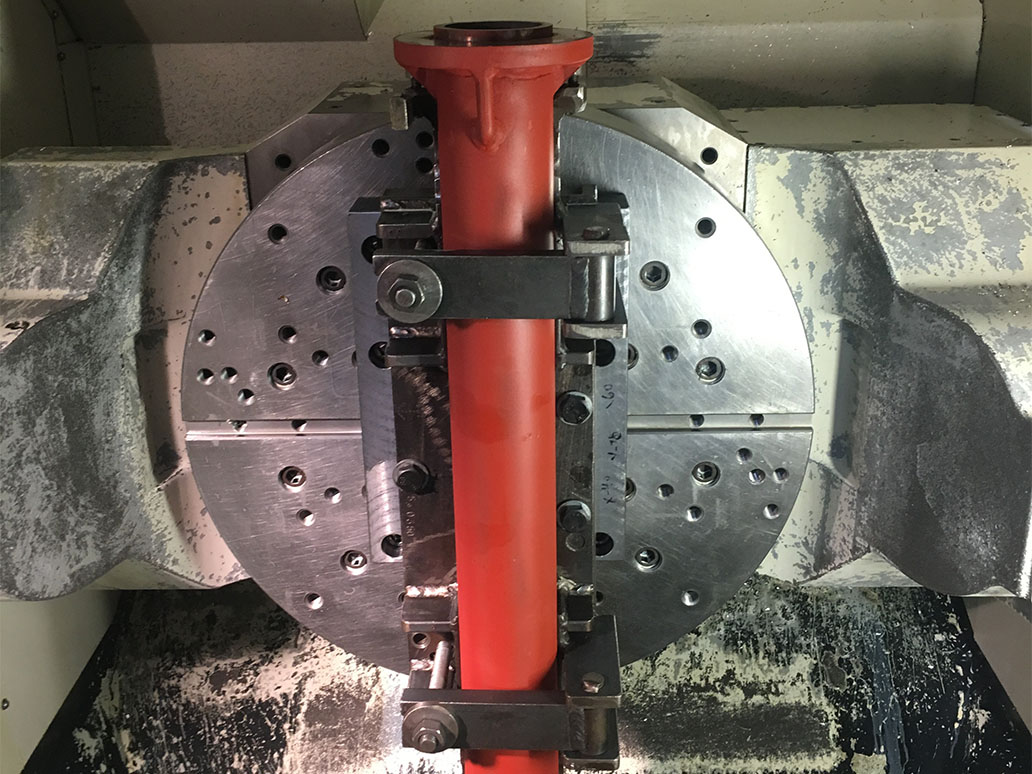

• Cutting Tools: High tensile tool steels can be used to produce cutting tools such as drills, end mills, reamers, and taps. Their exceptional hardness and wear resistance make them well-suited for high-speed machining operations, which results in improved tool life and enhanced cutting performance.

• Dies and Moulds: Dies and moulds for metal forming, plastic injection moulding, and die casting processes can also be created out of high tensile tool steels. Their high hardness and toughness allow them to withstand repeated mechanical stresses, preventing premature wear and ensuring dimensional accuracy in the final products.

• Cold Work Tooling: High tensile tool steels are widely employed in cold work tooling applications where materials are shaped and formed at or near room temperature. Some of these cold work tools include blanking, shearing, and stamping tools.

• Hot Work Tooling: In applications involving high-temperature environments like forging, extrusion, and die casting, high tensile tool steels with good heat resistance and thermal stability are preferred. These steels maintain their hardness and mechanical properties even at elevated temperatures, ensuring reliable performance during hot work processes.

High tensile tool steels play a vital role in modern machining processes due to their high hardness, wear resistance, toughness, and strength. These steels are essential in the production of cutting tools, dies, and moulds used in automotive, aerospace, metalworking, and plastics processing applications.

Optimized by: Netwizard SEO