Streamline production with CAD/CAM manufacturing by Aero Spec Engineering. Achieve intricate modelling, proper stimulation, and precise fabrication today!

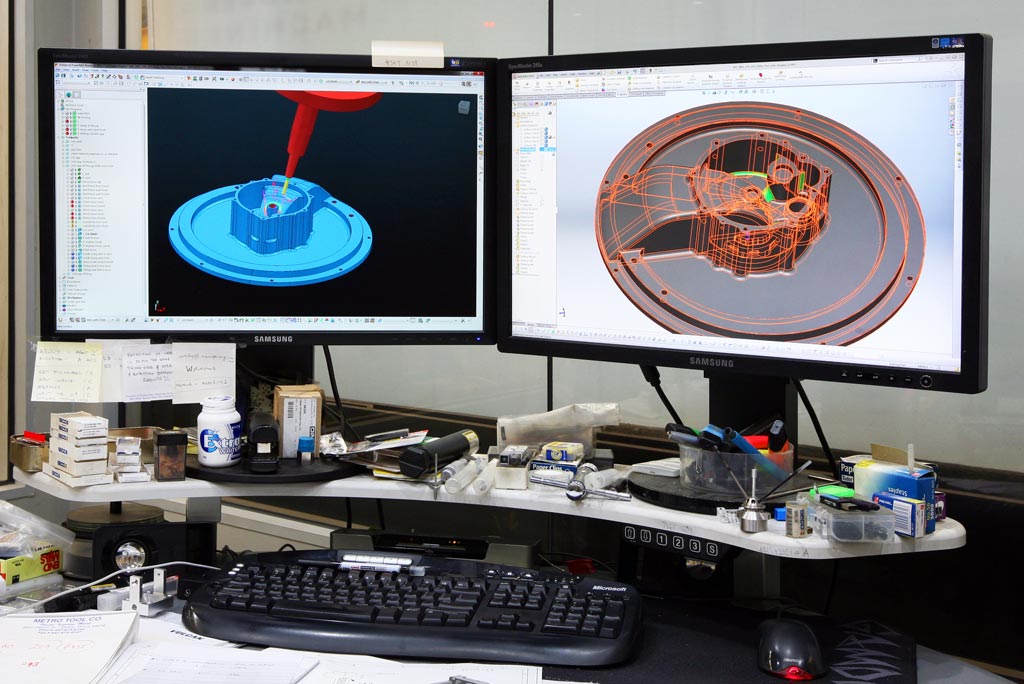

CAD/CAM solution drives significant efficiency gains across various industries. Integrating digital design with precision manufacturing, CAD/CAM or Computer-Aided Design/Computer-Aided Manufacturing not only accelerates the product development cycle but also enhances the quality and complexity of the final products.

The Connection of CAD and CAM

CAD technology has transformed the traditional drafting process into a highly efficient and versatile digital environment. Today, designers and engineers can generate detailed 3D models of products with unparalleled accuracy and speed. This shift not only reduces the time spent in the design phase but also allows for more complex and innovative solutions to be developed. The ability to quickly modify designs within CAD software significantly reduces errors and iterations, which leads to a more streamlined development process.

Once a model is created in a CAD system, CAM technology takes over to turn the digital design into a physical reality. CAM systems use the detailed models and assemblies generated in CAD software to control machine tools and processes, such as CNC or Computer Numerical Control machining, 3D printing, laser cutting, and more.

This direct link between digital designs and manufacturing tools makes sure that the final products are fabricated with a high degree of precision, closely matching the original specifications. Aero Spec Engineering takes advantage of this link to fabricate parts and components without any issues.

CAD/CAM Solution: Main Benefits

Aero Spec Engineering maximises CAD/CAM as it provides tons of benefits.

One of the key benefits of CAD/CAM technology is the ability to simulate the manufacturing process and product performance before any physical fabrication begins. These simulations can predict how a product will behave under various conditions and identify potential issues with the design, materials, or manufacturing process. By addressing these issues early in the development cycle, we can avoid costly errors and rework, further enhancing efficiency and reducing time to market.

Likewise, CAD/CAM solution opens up new possibilities for customisation and complexity in product design that would be difficult, if not impossible, to achieve with traditional manufacturing techniques. From custom dental implants and orthotics to aerospace components and intricate jewellery designs, CAD/CAM allows for high levels of customisation without increasing production costs significantly.

By optimising manufacturing processes and improving material utilisation, CAD/CAM solution also helps in reducing waste and streamlining production. Efficient nesting of parts on raw material sheets, precise control of cutting tools, and the minimisation of human error all contribute to more sustainable manufacturing practices and lower production costs. Furthermore, the ability to simulate and plan manufacturing processes helps in optimising production schedules and reducing downtime.

Work with Aero Spec Engineering

CAD/CAM solution by Aero Spec Engineering offers a holistic approach to design, simulation, and fabrication that drives efficiency, reduces errors, and fosters innovation. By seamlessly integrating the digital and physical aspects of production, CAD/CAM technology not only enhances our manufacturing capabilities but also provides new avenues for creativity and customisation. The role of CAD/CAM solution in manufacturing is set to become even more pivotal as it shapes the future of production.

Optimized by: Netwizard SEO