Precision Engineering Services: Food Equipment Design Accuracy

16 January 2024

Elevate food equipment design with precision engineering services by Aero Spec Engineering. Enhance efficiency in the food industry. Call +613 9547 8178.

The food industry takes advantage of a variety of equipment and machines to make sure its processes are conducted optimally. Some of them include refrigerators, freezers, food processors, ranges, ovens, mixers, and blenders. While they carry out different functions, they all require well-planned designs and structures to make them functional.

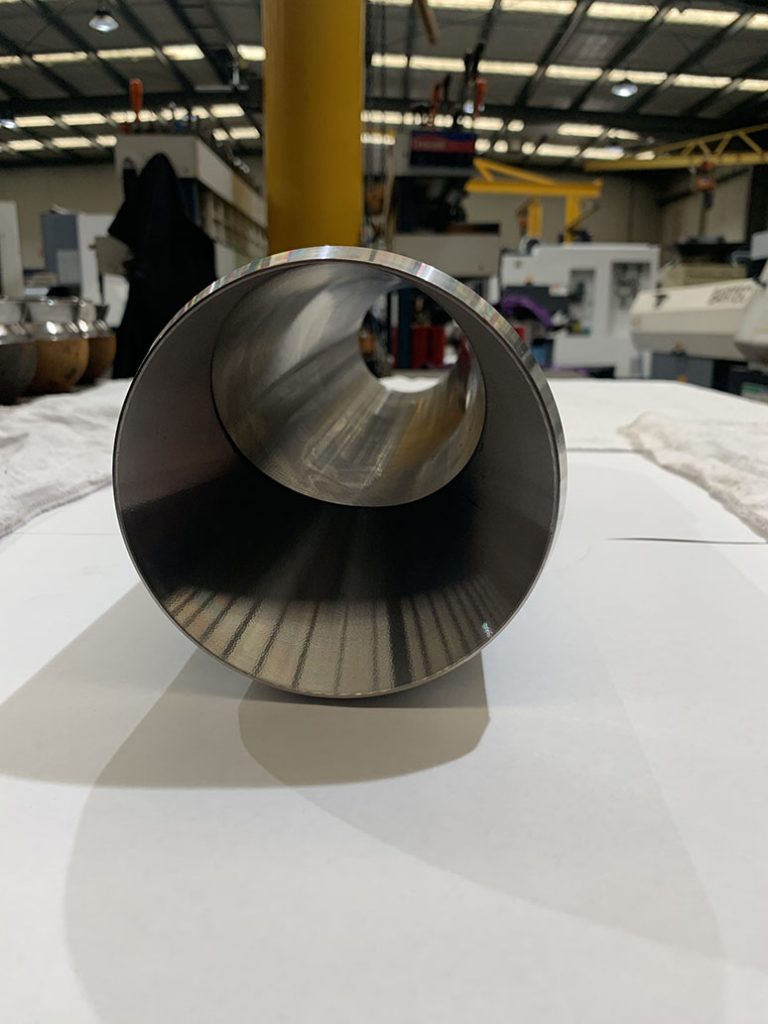

One thing that can ensure the accuracy of food equipment design is precision engineering. At Aero Spec Engineering, we provide precision engineering services to create a foundation for seamless operations and elevated performance in the food industry.

Precision Engineering for Food Equipment

Precision engineering for food equipment involves the application of advanced engineering principles and techniques to design, manufacture, and maintain specialised machinery and equipment used in the food industry. Its primary goal is to achieve high levels of accuracy, reliability, and efficiency in the production and processing of food, ensuring that equipment meets stringent hygiene standards, complies with regulations, and contributes to optimal food quality and safety.

Some aspects of precision engineering for food equipment include material selection, design precision, hygienic design, sanitary construction, automation, efficiency, cleanability, and reliability.

Collaborating with Aero Spec Engineering

At Aero Spec Engineering, we maximise precision engineering services to design and produce a wide array of food equipment pieces and components. When you collaborate with us, you can attain the following advantages.

- Tailored Solutions: Our precision engineering services excel in providing tailored solutions for a diverse range of food equipment. Each piece of equipment demands a unique design approach, and our precision engineering services ensure that every detail is meticulously considered to meet specific operational requirements.

- Enhanced Operational Efficiency: Precision engineering contributes to the optimisation of food equipment functionality, resulting in enhanced operational efficiency. Whether it’s a conveyor system, a dough kneader, or a food processing line, accuracy in design ensures that the equipment operates seamlessly, reducing downtime and maximising productivity.

- Dependable Material Selection: Aero Spec Engineering also prioritises the selection of materials that not only meet stringent hygiene standards but also withstand the rigours of daily use. Stainless steel, corrosion-resistant alloys, and food-grade plastics are among the carefully chosen materials for food equipment pieces to ensure both cleanliness and durability.

- Advanced Automation: Automation is a key feature in modern food equipment design, and our precision engineering services leverage advanced automation and control systems. From programmable logic controllers to smart sensors, these systems enhance the precision and reliability of equipment operation as well as facilitate improved monitoring and control of processes.

- Compliance with Standards: The food industry is subject to rigorous safety and quality standards. Aero Spec Engineering is well-versed in industry regulations and guidelines, ensuring that food equipment designs comply with the necessary standards. This commitment to compliance guarantees the safety of the end product and mitigates the risk of regulatory issues.

- Wastage Reduction: Precision engineering in food equipment design contributes to the reduction of wastage. Accurate design ensures that ingredients are processed efficiently, reducing losses and improving overall resource utilisation.

Precision engineering services by Aero Spec Engineering are instrumental in shaping the future of food equipment design. As the food industry continues to demand higher levels of efficiency, safety, and quality, we can ensure that every piece of equipment will meet and even exceed the evolving expectations of the modern food manufacturing or processing landscape.

Optimized by: Netwizard SEO