Unlock the potential of titanium with CNC machining from Aero Spec Engineering in Australia. Discover its unique properties for high-performance applications.

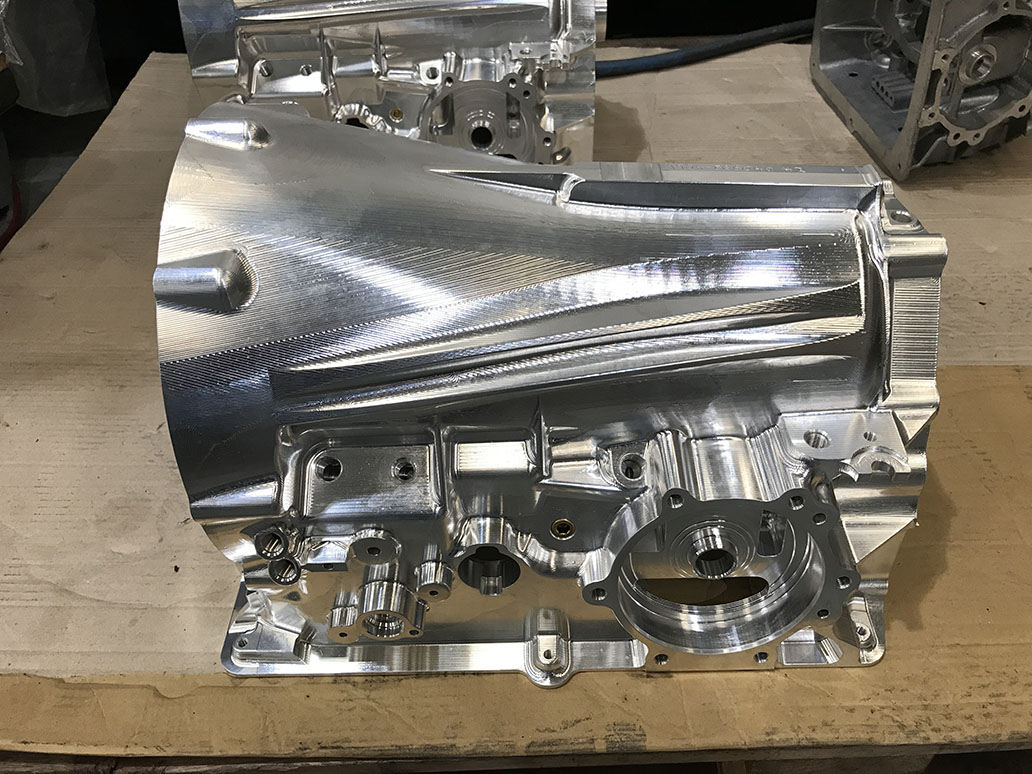

At Aero Spec Engineering, we’re at the forefront of titanium CNC machining for high-performance applications. Our advanced CNC technology allows us to unlock the full potential of titanium, crafting precision components for the most demanding industries. From aerospace to motorsports to medical industries, our expertise in titanium machining delivers unparalleled strength-to-weight ratios and corrosion resistance.

We push the boundaries of what’s possible with titanium, creating bespoke solutions that meet the exacting standards of our clients. Whether you’re after complex geometries or large-scale production runs, Aero Spec Engineering’s titanium CNC machining capabilities are geared to elevate your project to new heights.

Why Titanium?

Titanium is a truly remarkable metal prized for its unique combination of desirable qualities:

• Strength-to-weight ratio: Incredibly strong yet surprisingly lightweight, titanium boasts a superior strength-to-weight ratio compared to many other common metals like steel. This makes it ideal for applications where weight reduction is critical, such as in aerospace and motorsport components.

• Corrosion resistance: Titanium is naturally resistant to corrosion, making it a perfect choice for components exposed to harsh environments like saltwater, chemicals, and extreme temperatures.

• Biocompatibility: Implantable medical devices often rely on titanium due to its excellent biocompatibility, meaning it integrates well with the human body without causing rejection.

• High-Temperature Performance: Titanium maintains its strength at elevated temperatures, making it invaluable for turbine engines and other high-heat applications in aerospace and industrial settings.

CNC Machining for Titanium Materials

CNC machining is a subtractive manufacturing process that uses computer-controlled machines to precisely remove material from a solid block to create the desired final product. Here’s how CNC machining unlocks the full potential of titanium for high-performance applications:

• Precision and repeatability: CNC machining offers unparalleled precision and repeatability. This is crucial for creating complex titanium components with tight tolerances, ensuring exceptional performance and consistent quality.

• Reduced waste: CNC machining minimises material waste compared to traditional methods. This is particularly important for titanium, a valuable and often expensive material.

• Design flexibility: Advanced CNC machines can handle intricate geometries and complex designs that would be impossible to achieve with manual machining. This allows engineers to push the boundaries of design and create high-performance parts with unique functionalities.

• Versatility: CNC machining can handle a wide range of titanium grades, ensuring the perfect material selection for each specific application.

Titanium for Various Industries

Although titanium struggles to conduct heat away from the cutting zone. Here are some of the high-performance applications where CNC machining shines with titanium:

Aerospace components – From lightweight airframes to high-thrust engine parts, CNC-machined titanium components play a vital role in modern aircraft due to their exceptional strength-to-weight ratio and high tolerance for extreme temperatures.

Medical implants – Orthopaedic implants and other medical devices often rely on biocompatible, corrosion-resistant titanium. CNC machining ensures these implants are precisely manufactured for perfect fit and function within the human body.

Unleash the Potential of Titanium with Aero Spec Engineering

At Aero Spec Engineering, we possess the expertise and advanced CNC machining capabilities to unlock the full potential of titanium for your high-performance applications. Our team of engineers will work closely with you to understand your specific needs and select the most suitable grade of titanium for the job.

Optimized by: Netwizard SEO